Advantages

Workshop

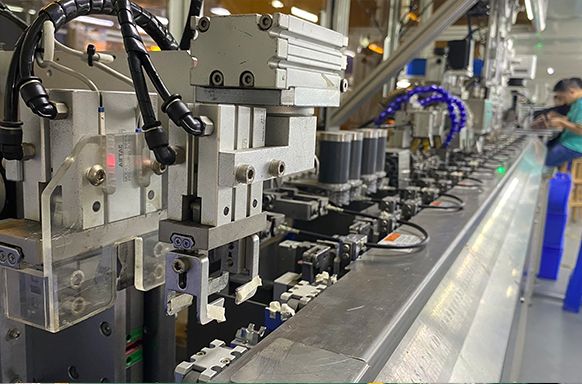

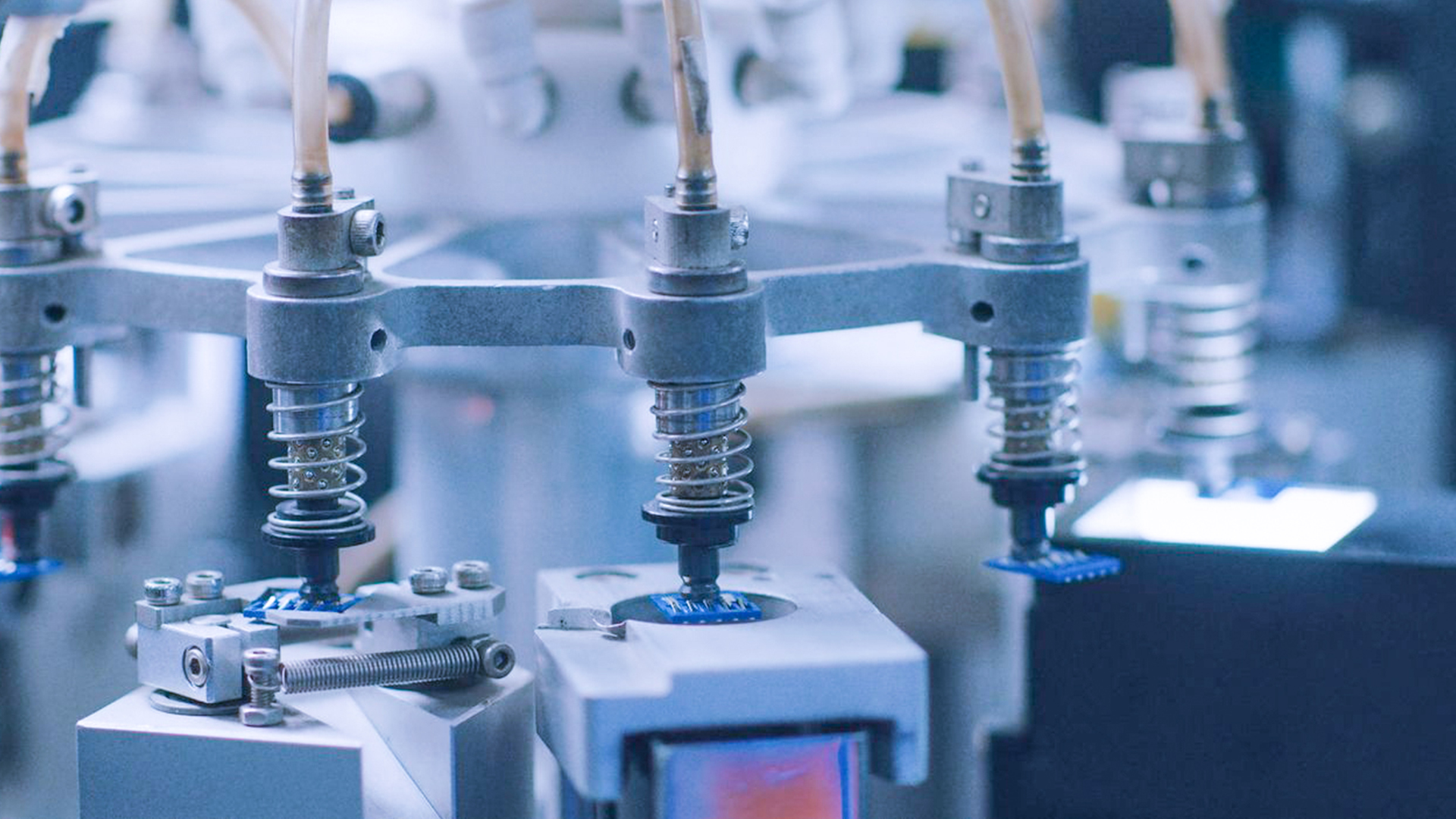

Our production department is the production center, which has six departments: Production Planning Department, Stamping Department, Injection Department, Wire Department, Connector Manufacturing Department and Seiko Device Department. Precision automation equipment is an important cornerstone of enterprise transformation and upgrading.We have professional automation structure design and electrical designers, and have established a complete automation design, parts processing, and automatic machine setup. With the advent of 5G technology and the era of Industry 4.0, we are gradually establishing a three-in-one intelligence of logistics, information flow and automation through the integration of advanced technologies such as automatic image inspection system, MES production management intelligence, EQC quality cloud data management, and robotic equipment chemical manufacturing technology.

-

With the advent of 5G technology and the era of Industry 4.0, we are gradually establishing a three-in-one intelligence of logistics, information flow and automation through the integration of advanced technologies such as automatic image inspection system, MES production management intelligence, EQC quality cloud data management, and robotic equipment. chemical manufacturing technology.

-

We have mastered the key statistical tolerance analysis technology, combined statistical concepts and manufacturing capabilities, and further improved our company's precision manufacturing level.

-

The manufacture of precision connectors uses integrated automation technology for many processes such as feeding, cutting, inserting, riveting, stacking, laser, laser welding, Mylar (polyester film), online monitoring, and automatic packaging. Cable) involving laser cutting, mechanical cutting, automatic tinning, automatic assembly of PCB (printed circuit board), automatic Hot Bar (hot pressing melting tin) welding and many other processes are semi-automatic technology. The automated production technology ensures the consistency and reliability of the products while obtaining considerable economic benefits.

-

The production adopts the composite automatic production technology of stamping, injection molding, assembly and testing. Industrial PLC (Programmable Logic Controller) is used between the machines/equipment of each process to realize information transfer, and real-time tracking of materials and machine conditions and feedback to relevant PMC (production management & material control), engineering, quality and production technicians, ensure the effective integration of logistics, information flow and automation.